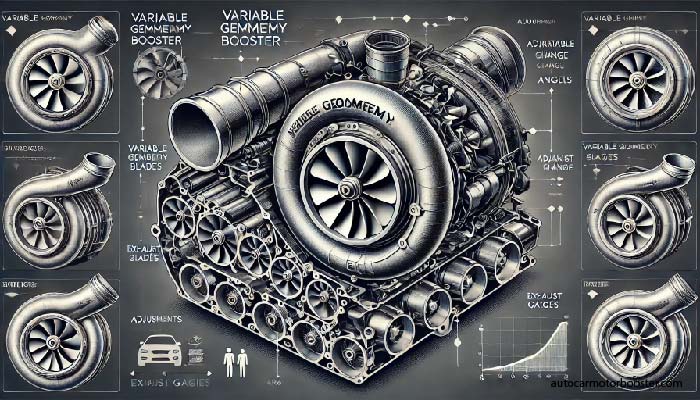

In the world of automotive engineering, variable geometry boosters (VGBs) have emerged as a game-changer in enhancing vehicle performance and efficiency. These systems are designed to optimize the airflow within an engine’s turbocharger, ultimately improving power output while reducing emissions. This article delves into the mechanics of variable geometry boosters, their benefits, and essential considerations for both engineers and automotive enthusiasts.

What are Variable Geometry Boosters?

Variable geometry boosters refer to a specific type of turbocharger that utilizes adjustable vanes to control the flow of exhaust gases. This innovative design allows for better matching of the turbocharger’s performance with the engine’s operating conditions. By adjusting the angle of the vanes, the turbocharger can maintain optimal boost pressure across a wide range of engine speeds, ensuring consistent performance and responsiveness.

How Do They Work?

The operation of a variable geometry booster involves several key components:

- Adjustable Vanes: These vanes can change their position based on the engine’s RPM and load conditions. At lower RPMs, the vanes close to increase exhaust gas velocity, providing quicker spool-up times. As RPMs rise, the vanes open to allow more exhaust flow, maximizing power output.

- Control Mechanism: A control system monitors the engine’s performance and adjusts the vanes accordingly. This can be done using electronic actuators or pneumatic systems, ensuring real-time optimization of turbocharger performance.

- Boost Pressure Management: By controlling the airflow, VGBs can maintain consistent boost pressure, preventing turbo lag and enhancing throttle response. This results in a more enjoyable driving experience and improved acceleration.

Benefits of Variable Geometry Boosters

- Improved Performance: One of the most significant advantages of VGBs is their ability to deliver power efficiently. By optimizing the airflow, these systems can enhance overall engine performance, especially in turbocharged engines.

- Reduced Emissions: With better fuel efficiency comes lower emissions. Variable geometry boosters help engines operate more efficiently, leading to reduced CO2 emissions and compliance with stringent environmental regulations.

- Enhanced Throttle Response: VGBs minimize turbo lag, providing a more immediate response when the driver accelerates. This enhances the overall driving experience, making vehicles more enjoyable to drive.

- Versatility Across Engine Types: These boosters can be applied to various engine configurations, including diesel and gasoline engines, making them a popular choice in modern automotive design.

- Fuel Efficiency: By improving the combustion process, VGBs can lead to better fuel economy, which is crucial for both consumers and manufacturers aiming to reduce operational costs.

Considerations When Using Variable Geometry Boosters

While the benefits of variable geometry boosters are substantial, there are several considerations to keep in mind:

- Complexity: The addition of VGBs increases the complexity of the turbocharger system. Engineers must ensure that the control systems are robust and reliable to avoid failures.

- Cost: Implementing variable geometry boosters can add to the overall cost of the engine design. Manufacturers need to weigh the benefits against the increased production costs.

- Maintenance: Due to their intricate design, VGBs may require more maintenance than traditional turbochargers. Regular inspections are essential to ensure longevity and performance.

- Compatibility: Not all engines are suitable for VGB installation. It’s vital to assess whether the engine design can accommodate the added complexity of variable geometry technology.

- Performance Tuning: To fully leverage the advantages of VGBs, performance tuning may be necessary. This involves adjusting engine parameters to optimize the benefits of the variable geometry system.

Conclusion

Variable geometry boosters represent a significant advancement in turbocharging technology, offering numerous benefits that enhance engine performance, efficiency, and emissions control. Understanding how they work and their implications is essential for anyone involved in automotive engineering or passionate about performance vehicles. As technology continues to evolve, VGBs will likely play a crucial role in the future of automotive design.

FAQs

1. What are variable geometry boosters?

Variable geometry boosters are turbochargers with adjustable vanes that optimize airflow and boost pressure across various engine speeds, enhancing performance and efficiency.

2. How do variable geometry boosters improve engine performance?

By adjusting the position of the vanes, VGBs increase exhaust gas velocity at low RPMs and allow for more exhaust flow at high RPMs, reducing turbo lag and improving throttle response.

3. Are variable geometry boosters suitable for all engines?

While VGBs can be applied to many engine types, not all engines are compatible. It’s essential to assess engine design and requirements before installation.

4. What maintenance do variable geometry boosters require?

VGBs may require more maintenance than traditional turbochargers due to their complexity. Regular inspections and servicing are essential for optimal performance.

5. Can variable geometry boosters help reduce emissions?

Yes, by improving fuel efficiency and optimizing the combustion process, variable geometry boosters contribute to lower CO2 emissions, aiding compliance with environmental regulations.

If Like This Article Visit Our Website. Collect From Wekiapedia