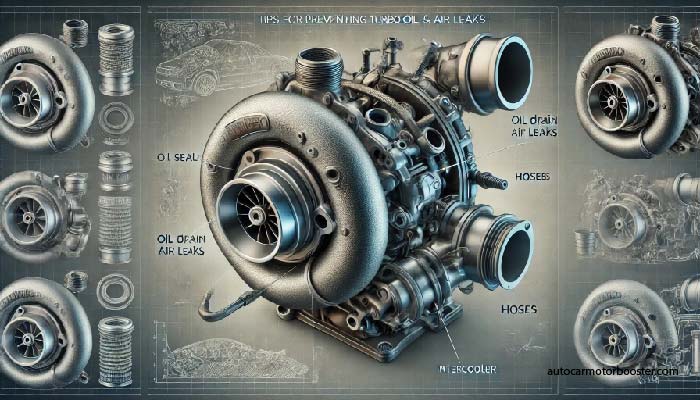

Preventing Turbo Oil and Air Leaks Effectively Modern turbocharged engines enhance performance, but they’re prone to oil and air leaks if not maintained properly. Both turbo oil leaks and air leaks can lead to reduced engine efficiency, damage, and costly repairs. By understanding the causes and implementing preventative measures, you can maintain your turbo’s performance effectively.

1. Understanding Turbo Oil Leaks

A turbo oil leak happens when oil escapes from the turbocharger system, often due to worn-out seals or high pressure. This leak can lead to performance issues, decreased fuel efficiency, and, in severe cases, turbocharger failure.

Common causes of turbo oil leaks include:

- Faulty Seals – Seals can degrade over time, allowing oil to seep through.

- Blocked Oil Drain – If oil isn’t drained properly, it can accumulate and create leaks.

- Excessive Oil Pressure – High pressure in the turbocharger system can force oil through seals.

2. Tips for Preventing Turbo Oil Leaks

Implementing routine checks and using quality components can help prevent leaks effectively.

- Check and Replace Seals Regularly: Regularly inspect turbo seals and replace them if worn or damaged. Quality seals ensure better resistance to pressure and heat, reducing leak risk.

- Ensure Proper Oil Drainage: Make sure the oil drain line is free of blockages. Clean the line periodically to prevent oil buildup.

- Use High-Quality Oil and Maintain Correct Pressure: Choosing the right oil and maintaining correct pressure levels are critical. Low-quality oil or excessive oil pressure can increase the risk of leaks.

3. Understanding Turbo Air Leaks

Turbo air leaks occur when there’s an unwanted escape of air in the turbo system, often due to damaged hoses or loose clamps. These leaks can reduce boost pressure and overall engine performance, causing lag and lower fuel efficiency.

Common causes of turbo air leaks include:

- Cracked or Loose Hoses – Hoses wear down over time, leading to potential air leaks.

- Improperly Secured Clamps – Loose clamps can cause air to escape, decreasing performance.

- Damaged Intercooler – A damaged or leaking intercooler may lead to air loss.

4. Tips for Preventing Turbo Air Leaks

To maintain air pressure in the turbo system, follow these preventative steps:

- Inspect Hoses and Clamps Regularly: Examine hoses and clamps for signs of wear, cracks, or looseness. Tighten or replace any worn-out parts.

- Use High-Quality Parts: Invest in quality hoses and clamps that are built to withstand high pressures. This small investment can prevent expensive repairs.

- Check the Intercooler for Damage: Ensure the intercooler is free from any leaks or damage. Replace or repair it as necessary to prevent air loss.

5. Regular Maintenance for Long-Term Prevention

The most effective way to prevent both turbo oil and air leaks is through consistent maintenance. Make it a habit to check for early signs of leaks and replace any faulty parts as soon as possible. Use the right oil, parts, and quality seals to extend the life of your turbocharger and optimize performance.

Frequently Asked Questions (FAQs)

Q1: What are the signs of a turbo oil leak?

A1: Common signs include blue smoke from the exhaust, reduced power, and the presence of oil around the turbocharger. Early detection helps prevent severe damage.

Q2: How can I prevent turbo air leaks in the long term?

A2: Regularly check hoses, clamps, and the intercooler for any damage or looseness. Use quality parts designed for turbo systems to prevent wear and tear.

Q3: Why does my turbo leak oil after installation?

A3: Oil leaks post-installation often happen due to improperly fitted seals or high oil pressure. Ensure all seals are correctly installed and maintain recommended pressure levels.

Q4: Can low-quality oil lead to turbo leaks?

A4: Yes, low-quality oil can increase the risk of leaks by failing to lubricate and seal properly, leading to worn-out seals and excess pressure in the turbo system.

Q5: How often should I inspect my turbo system?

A5: It’s advisable to inspect the turbo system every 5,000 to 10,000 miles or as part of regular vehicle maintenance. More frequent checks can prevent costly repairs.

If Like This Article Visit Our Website. Collect From Wekiapedia