Introduction

In modern automotive engineering, turbochargers have revolutionized the way engines perform. Among the innovative designs, Variable Geometry Turbochargers (VGTs) stand out as a significant advancement. This article explores how VGTs are transforming vehicle performance, making them a game changer in the industry.

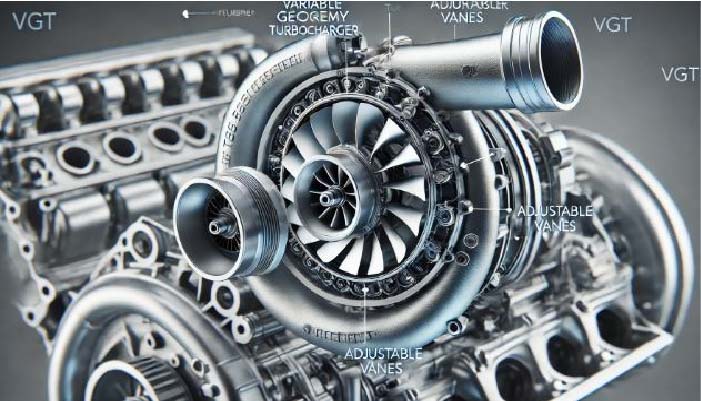

What is a Variable Geometry Turbocharger (VGT)?

A Variable Geometry Turbocharger (VGT) is a turbocharging system that adjusts its turbine’s geometry based on engine demands. Unlike traditional fixed-geometry turbochargers, VGTs can alter the position of the turbine vanes, optimizing airflow for various engine speeds and loads. This flexibility results in better fuel efficiency and lower emissions, making VGTs a popular choice for modern vehicles.

How VGTs Work

The core functionality of a VGT lies in its adjustable vanes around the turbine. These vanes can change their angle to control the exhaust flow to the turbine wheel:

- At low engine speeds, the vanes narrow, increasing the exhaust gas velocity. This helps in producing more boost pressure at lower RPMs.

- At high engine speeds, the vanes open up, reducing exhaust resistance and preventing turbo lag.

This dynamic adjustment ensures a balance between power and efficiency across all driving conditions.

Advantages of Variable Geometry Turbochargers

- Improved Performance: VGTs provide higher boost at low RPMs, enhancing throttle response and torque delivery.

- Better Fuel Efficiency: Optimized airflow management leads to less fuel consumption, especially in diesel engines.

- Lower Emissions: By managing the exhaust gases more effectively, VGTs contribute to reducing harmful emissions like NOx and CO2.

- Turbo Lag Reduction: The ability to adjust vane positions reduces turbo lag significantly, offering a smoother driving experience.

- Enhanced Durability: VGTs, when well-maintained, tend to last longer due to their efficient operation and adaptability.

VGTs vs. Traditional Turbochargers

Traditional turbochargers operate with fixed geometry, meaning they are designed to perform optimally at specific RPM ranges. Here’s how they differ from VGTs:

- Boost Control: Fixed-geometry turbochargers may suffer from turbo lag at low RPMs, whereas VGTs adjust to provide consistent power.

- Efficiency: VGTs can adapt to a broader range of driving conditions, making them more fuel-efficient.

- Emissions: VGTs are more environmentally friendly due to their ability to manage exhaust gases better.

Applications of VGT Technology

VGTs are widely used in diesel engines due to their efficiency and performance benefits at low RPMs. They are commonly found in:

- Passenger Vehicles: VGTs are a staple in modern diesel cars and some gasoline-powered vehicles.

- Commercial Trucks: Their fuel efficiency and ability to deliver torque at low speeds make them ideal for heavy-duty trucks.

- Marine Engines: Many marine diesel engines use VGTs for enhanced performance and durability in varying conditions.

- Aviation: Some small aircraft engines have adopted VGT technology for better altitude performance.

The Future of VGTs

As emissions regulations become more stringent and the demand for fuel-efficient engines grows, the future of Variable Geometry Turbochargers looks promising. With advancements in materials and electronic control systems, VGTs are likely to become even more effective and widespread across different vehicle types, including hybrid and electric vehicles.

Conclusion

Variable Geometry Turbochargers are undoubtedly a game changer in modern automotive engineering. Their ability to optimize engine performance, improve fuel efficiency, and reduce emissions positions them as a key component in the future of transportation.

FAQs

Q1: What makes a VGT different from a regular turbocharger?

A: VGTs have adjustable vanes that control exhaust gas flow, while regular turbochargers have a fixed design. This allows VGTs to provide better performance across a wider range of RPMs.

Q2: Are VGTs used in gasoline engines?

A: Yes, although VGTs are more common in diesel engines, they are also used in some high-performance gasoline engines for better efficiency and power delivery.

Q3: Can a VGT help reduce fuel consumption?

A: Yes, by optimizing the turbo boost across different driving conditions, VGTs improve fuel efficiency, particularly in vehicles with diesel engines.

Q4: Do VGTs require special maintenance?

A: VGTs do not require significantly different maintenance than traditional turbochargers, but ensuring clean oil and proper engine care is crucial for longevity.

Q5: Are there any downsides to VGTs?

A: While VGTs offer many advantages, they can be more expensive and complex compared to traditional turbochargers, requiring more advanced control systems.

If Like This Article Visit Our Website. Collect From Wekiapedia